Suppliers

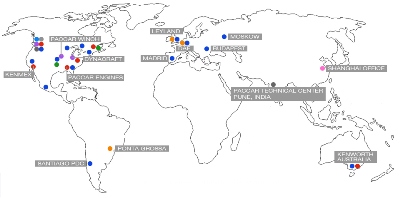

Leyland Trucks Purchasing is part of the PACCAR Global Purchasing Organisation.

This organisation is directly responsible for the purchasing of truck production parts for all PACCAR plants and is split in several groups. Each Group is responsible for managing the sourcing of the specific products/projects through approved PACCAR suppliers.

PACCAR Purchasing Europe is based through offices in Leyland (UK), and Eindhoven (NL). The global PACCAR purchasing policy applies to all locations and for all products.

-

How to become a PACCAR supplier

If you meet the criteria and want to apply to become a supplier to PACCAR Europe, you can download the Supplier Questionnaire.

Download the suppliers questionnaire

Please send your completed questionnaire to the following address:

PACCAR Purchasing Europe

Leyland Trucks

Croston Road

Leyland

PR26 6LZ

We will use this questionnaire to gain a better insight into your organization and the way in which it measures to the five selection criteria. We would like to thank you in advance for your interest in PACCAR Europe. If your information meets our needs, we will contact you.

Purchasing

Leyland Trucks applies the following Purchasing Conditions: Purchasing Conditions

-

Supply Management Vision

Total quality

The purchasing policy of Leyland Trucks is consistent with the purchasing policy of PACCAR and based on the long term vision and strategy. The customer is given a central place in this strategy, for instance by providing excellent pre and after sales service.

We aimat partnerships within the whole value chain, and base our business processes on "total quality". The overall business strategy gives much attention to downstream activities, thus shifting the focus to the customers.

A key element of being able to offer a total quality solution is maintaining an efficient supply chain. This is why suppliers are key to the success of our business and why we operate strategic supply management. We need you all to play a part in this success.

- We buy products unless in-house development and/or production give a competitive advantage which can be passed onto the Customer

- We aim at suppliers who are able to deliver globally to PACCAR companies and therefore offer efficient and innovative solutions to the whole group.

- There is intensive co-operation between our business and suppliers, with the aim at sustaining long-term relationships.

- We are selective in choosing its suppliers and want to achieve more with fewer, strategic, suppliers.

- We involve suppliers at an early stage (from the definition phase) in new projects and developments enabling customer satisfaction.

- We give substance to "Strategic Supply Management" in an effective, proactive and interdisciplinary manner in the following five areas:

1. Quality

We ensures that goods and services comply with the order specifications in terms of quality and environmental requirements and continually monitors the quality of the flow of incoming goods. Furthermore, Purchasing wants the production processes of goods and services to show continuous improvement with regard to cost, quality and environmental impact. Innovation at all stages in the process is essential to maintain the market leading position that Leyland Trucks holds in the UK.

2. Logistics

At Leyland Trucks we produce according to the build-to-order strategy. This means that trucks are only built after they have been sold. Suppliers must therefore be able to provide continuity, reliability and flexibility of supply. Frequent, fast and faultless communication between us and our suppliers, and EDI is one of the tools used to realise this.

3. Know-how

Suppliers should invest heavily in research and development, looking at new technology and know-how of new products and systems. This should be shared with us at an early stage and co-operation formed. The cutting edge solutions required to maintain the successful product depends on the know how in the supply base. The Purchasing Department is responsible for keeping abreast of technological developments in the market and for spreading this knowledge within the organisation.

4. Competitive position

The supplier must have both a favourable market position and financial position. The management strategy in the Supplier organisation should align with that of PACCAR. The supplier needs to demonstrate good financial management and long term planning.

5. Total costs

The total costs within the value chain must be as low as possible, so that a competitive price can be set for the final product. Besides showing excellent performance with respect to the above-mentioned aspects, our suppliers are expected to participate in the various projects initiated within the Purchasing Department, such as Six Sigma projects and projects to improve products and processes through a Cost Management Programme . These projects enable continuous improvement and optimisation as regards costs, quality and functionality. -

Deployment of purchasing strategy

Key Strategic

Efforts are deployed to realise the purchasing strategy:

Supply market intelligence

Market information is gathered in a structured manner. This information is necessary in order to make a sound purchasing decision in accordance with the company policy. A clear picture of what is available in the market, how suppliers perform and how innovative suppliers are will all factor into that decision making process.

Long-term relationships

The supplier is expected to co-operate intensively with us. PACCAR wants to keep abreast of the supplier's possibilities and to make optimum use of his knowledge. Together with the supplier, the purchasing department will set challenging goals that give a win-win situation for the supplier as well as the PACCAR organisation. In this context, Leyland Trucks, along with all other PACCAR locations, participates in the Cost Management Programme, which enables adequate implementation of process and product improvement.

Restructuring of the supply base

PACCARs policy is aimed at buying more from fewer suppliers. This is achieved by finding synergies within our global organisation , the clustering of groups of products purchased from one supplier, and the purchasing of systems of a higher assembly level. Suppliers are only selected if they comply with the company purchasing policy.

Early supplier involvement

We want to make use of the know-how and development capacity of the supplier. The supplier will be involved in the Product Creation Process at an early stage and is expected to offer innovative solutions which improve the product that is jointly offered to the customer.

Quality assurance

The characteristics of the quality policy are: proactive and continuous improvement. A supplier's production processes must conform to Leyland's quality requirements (drawn up in accordance with ISO guidelines). Quality procedures and techniques must already be applied in the product development phase. Six Sigma is a technique applied by the PACCAR group to achieve a higher quality level. Suppliers are expected to co-operate closely with purchasing and other Leyland functions in devising, working through and closing Six Sigma projects with the aim of implementing improvements at multiple steps in the chain.

Logistics agreement & performance measurement

For every supplier not only commercial and quality agreements, but also individual logistic agreements are stipulated, for example in the logistic section of the purchase contract and the packaging agreement. In addition, the performance of every supplier is measured by Leyland Trucks and reported to the supplier.

Conclusion

Supply Management represents our purchasing vision, which helps us to be competitive in the truck market. We have set challenging goals for ourselves and our suppliers, and we shall mobilise the necessary capacity and supporting systems to achieve these goals. We expect our suppliers to work together with us to make Supply Management a success, for instance by starting continuous improvement projects and quality projects such as Six Sigma. We will only be successful if we work together to meet the wishes and requirements of our customers. Our suppliers of today are our co-designers, co-producers, co-developers and partners of tomorrow.

-

Cost Management Partnership

PACCAR is committed to being the value leader in the industry, providing the best quality products to its customers. PACCAR has the same expectations of its supply base, and looks for their leadership in continuous quality improvement, increased productivity, and cost reduction.

PACCAR's Cost Management Partnership (CMP) program provides a mechanism for suppliers to submit cost reduction ideas based upon new technologies, tooling, materials, logistics, etc., to PACCAR Purchasing.

By taking part in the CMP programme, suppliers are working to secure their competitive position at PACCAR. Suppliers also reap the benefits of productivity improvements.

To participate, suppliers should review the booklet and contact the Purchasing department at Leyland to discuss ideas and required support documentation. -

PACCARs preferred suppliers

Excellent performance

Every supplier of PACCAR meets at least the requirements laid down in the Supply Management Vision. In addition, PACCAR has a number of "Preferred Suppliers" who continuously perform excellently with respect to the above-mentioned aspects and who meet a number of additional requirements.

The Preferred Suppliers list of PACCAR is available here. -

Suppliers and logistics

Build-to-order

At Leyland, trucks are only built when they have been sold, the "Build-to-Order" strategy. The logistic goals derive from the Build-to-Order strategy.

Leyland's logistic goals

The primary logistic goal is delivery reliability. When a customer sends his order to Leyland Trucks he is given a delivery date for his truck; he then gears his business to this date, so it is of the utmost importance that this delivery date is achieved. Parts are a critical element in supporting this objective, so they must arrive when requested - as per the schedule.

The second logistic goal that we shall mention here is speed and reaction time: throughput times along the entire chain must be short, both physically and administratively. Physical speed is achieved by such means as appropriate transport frequencies / lot sizes, administrative speed by means of EDI communication, direct order entry, etc. On the one hand this is necessary because time to market is short, on the other hand because it contributes to greater flexibility and efficiency for both parties.

A very important aspect, finally, is flexibility throughout the chain, since trucks are not built until they have been sold. In addition, the vehicles may have huge variations in design. This can lead to fluctuations in demand for capacity and materials and, as such, Supplier communication and response is paramount.

Logistic development at Leyland Trucks

In order to achieve its objectives, Leyland Trucks is constantly concerned with process improvement. Important elements in this are:

• low stock levels

• short administrative throughput times (EDI / Labelling),

• minimisation of unnecessary handling,

• integration of Leyland Trucks and supplier processes,

• optimising transport runs,

• optimising the size and spread of the supplier base,

• standardisation of parts, etc.

• returnable packaging

In addition, a great deal of effort is put into developing and implementing efficient systems for controlling all of these processes. The minimum total costs are always taken into account when deciding whether to implement the above process improvements.

Related information

About Leyland Trucks Ltd.

Leyland Trucks is one of Britain’s leading manufacturing companies.

Leyland Trucks, a PACCAR Company

Leyland Trucks, one of Britain’s leading manufacturing companies, is a wholly-owned subsidiary of PACCAR Inc.